collection

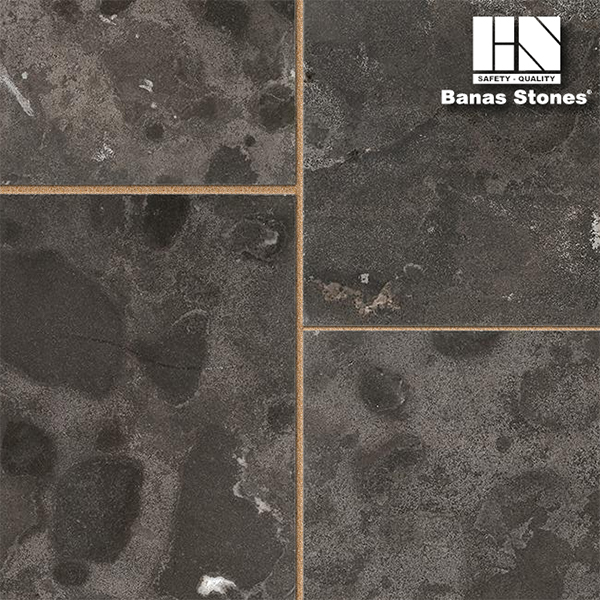

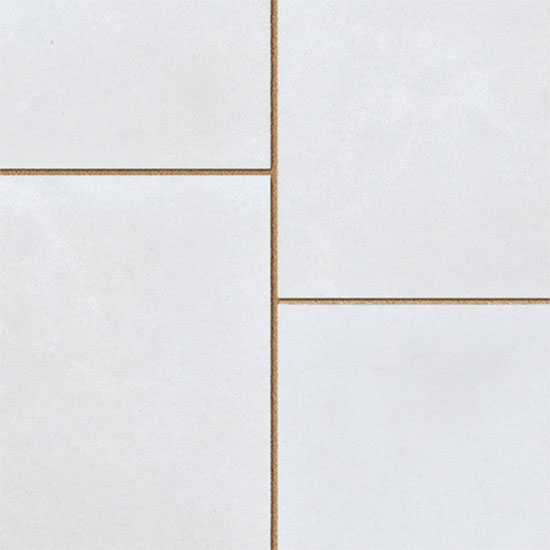

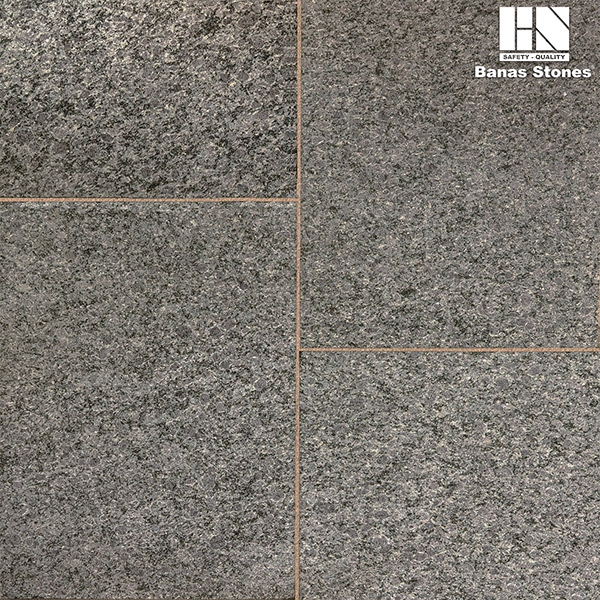

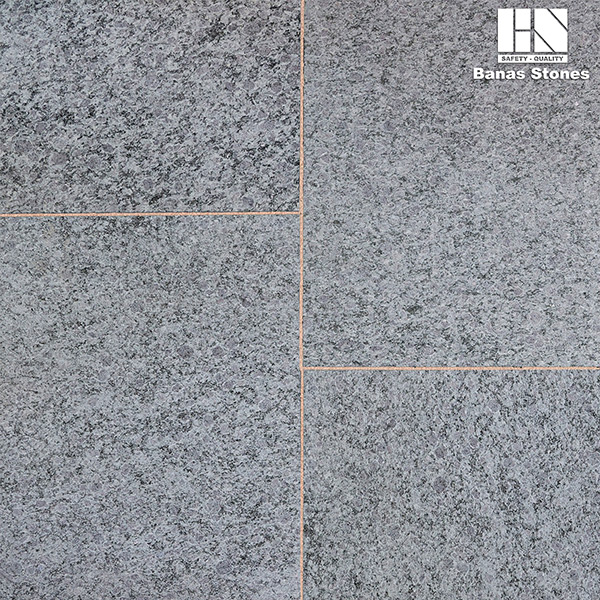

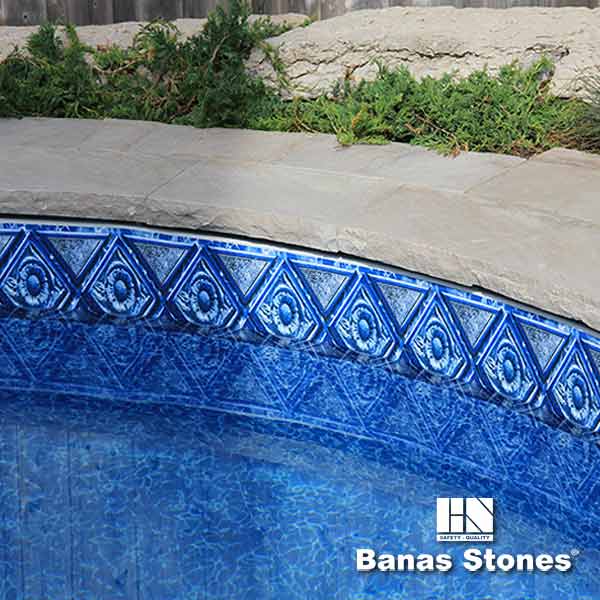

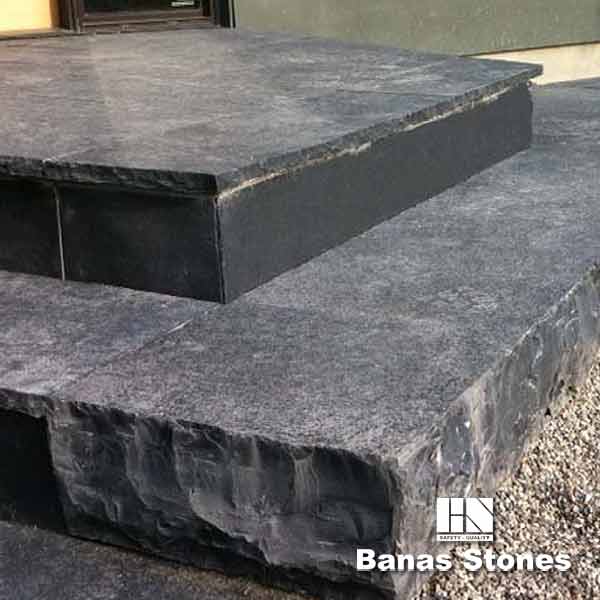

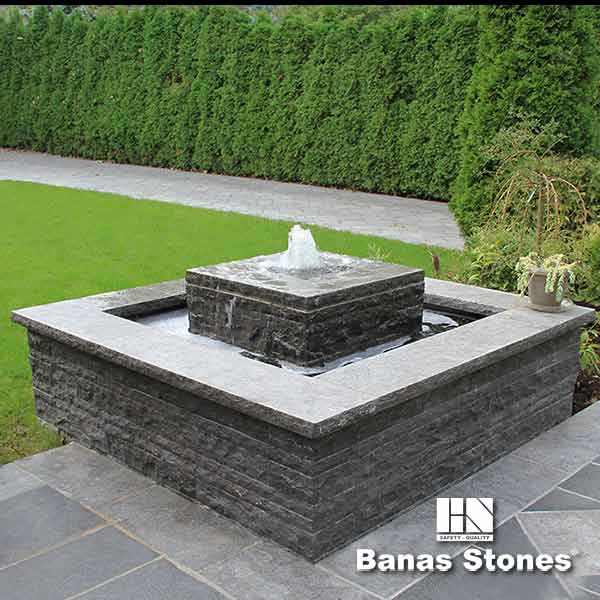

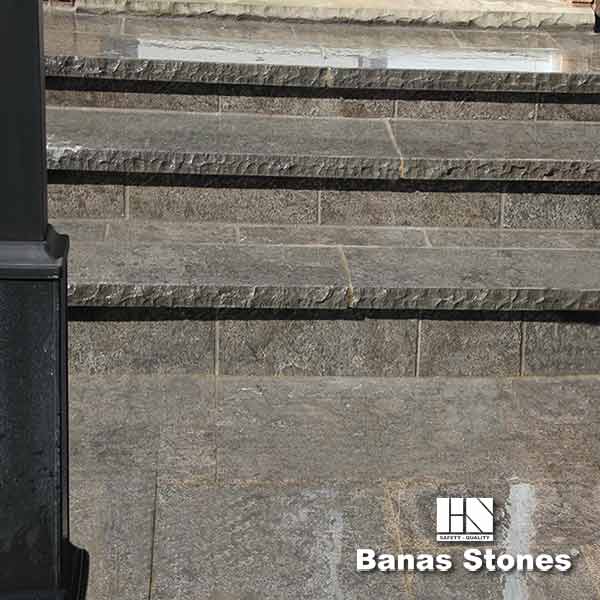

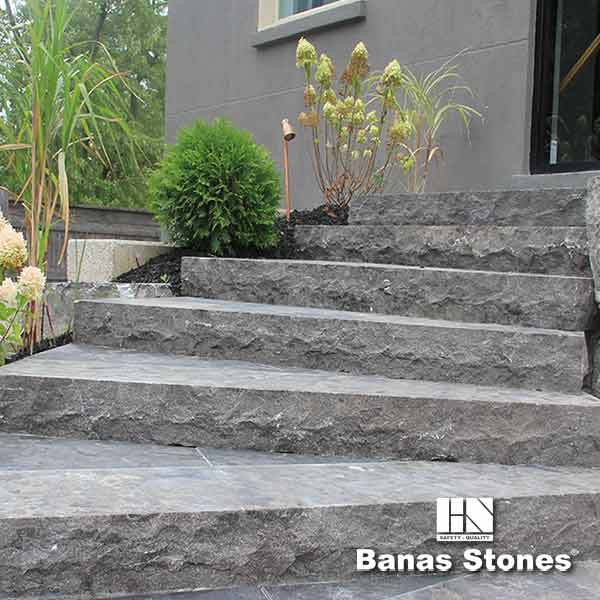

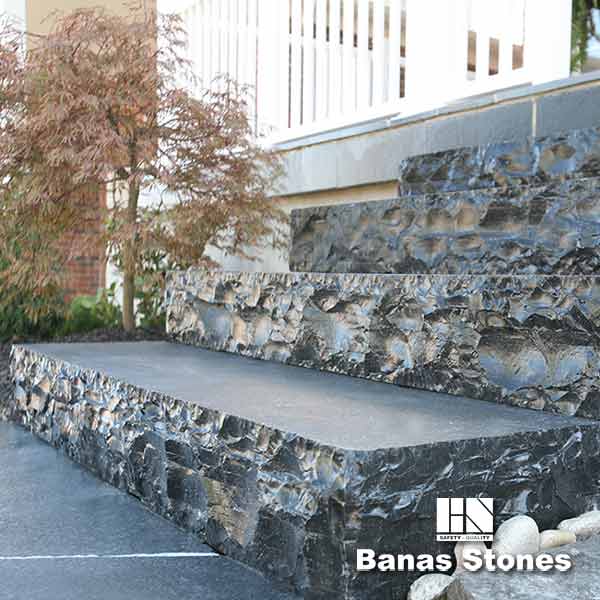

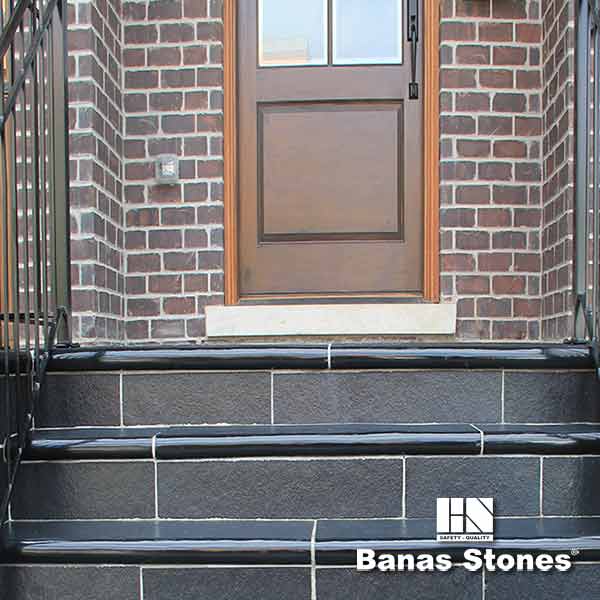

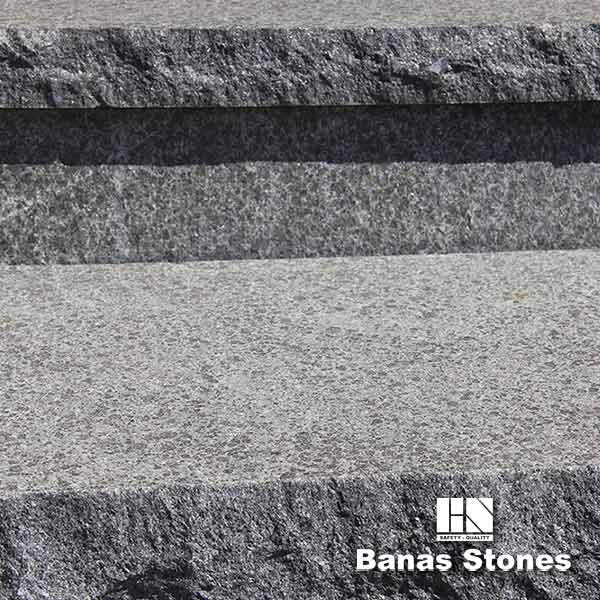

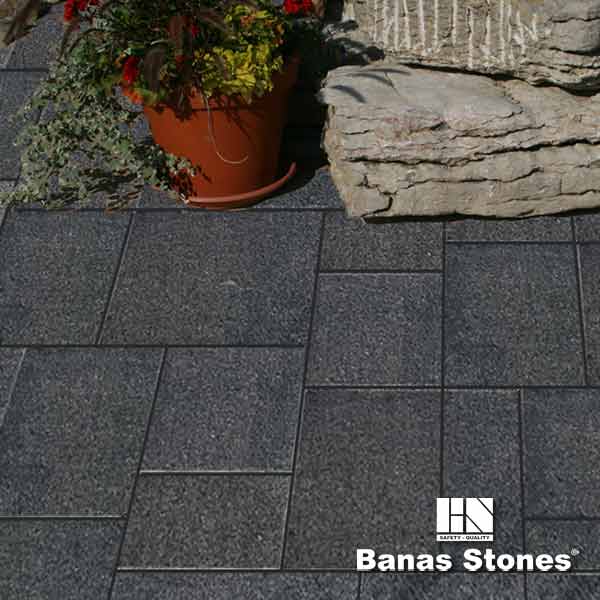

Banas Stones® is proud to offer a complete collection of high quality natural stone products in a variety of attractive colours and textures.

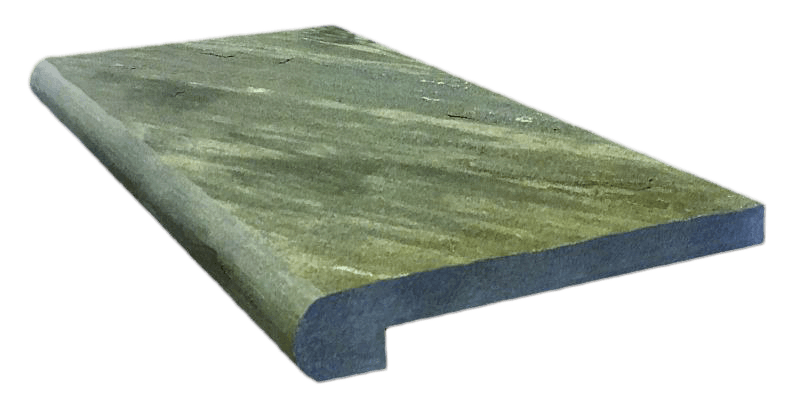

Travertine

ABOUT US

Banas Stones® is a major natural stone supplier and exporter throughout North America with a primary focus on establishing our own infrastructure and quarries ensuring excellent quality products.

All natural stone is quarried ethically with the highest safety and ethical standards.

ABOUT US

Banas Stones® is a major natural stone supplier and exporter throughout North America with a primary focus on establishing our own infrastructure and quarries ensuring excellent quality products.

All natural stone is quarried ethically with the highest safety and ethical standards.

The Banas Advantage

|

Our MissionDedicated to providing a complete collection of quality gauged, premium sandstone, limestone, and granite products. |

|

Our VisionWe are a family owned and operated company under the Banas® group umbrella offering top quality natural stone products globally. |

Core ValueWe have been setting the highest standards in service, quality, reliability, safety and cost containment in our industry for over 30 years. |

|

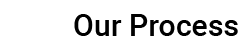

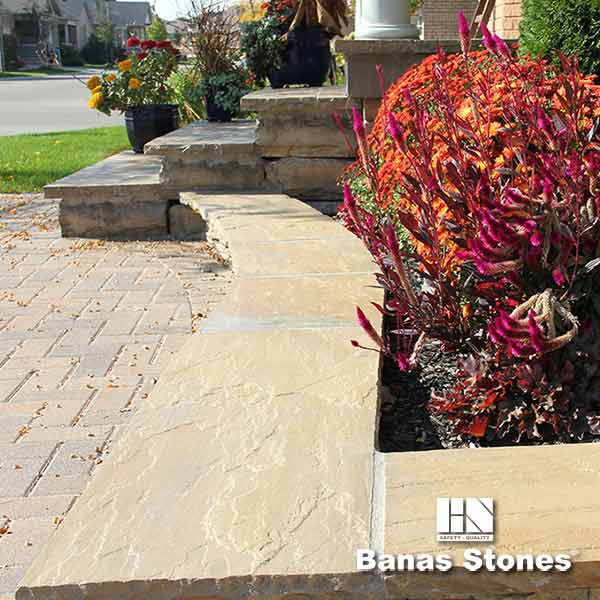

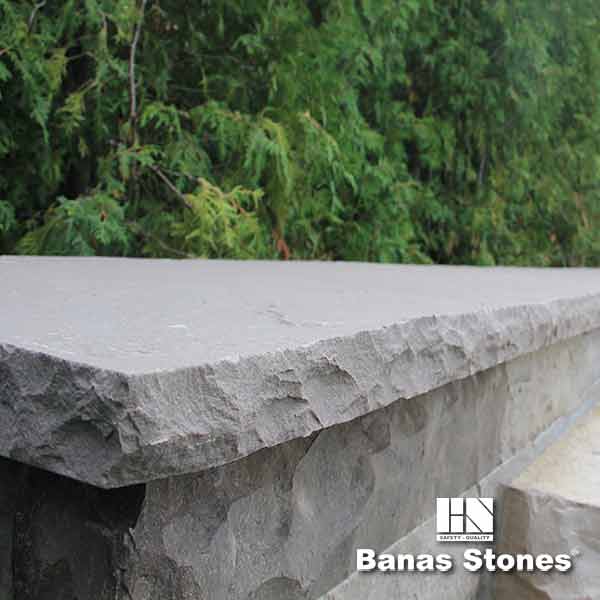

Our ProcessBanas Stones® owns and operates factories where the quarried stone is processed. |

|

Areas We Serve

Don’t See Your City ? No Worries, Just Call And We Can Schedule You !

Dedicated to providing a complete collection of quality gauged, premium sandstone, limestone, and granite products.

We are a family owned and operated company under the Banas® group umbrella offering top quality natural stone products globally.

We have been setting the highest standards in service, quality, reliability, safety and cost containment in our industry for over 30 years.

Banas Stones® owns and operates factories where the quarried stone is processed.

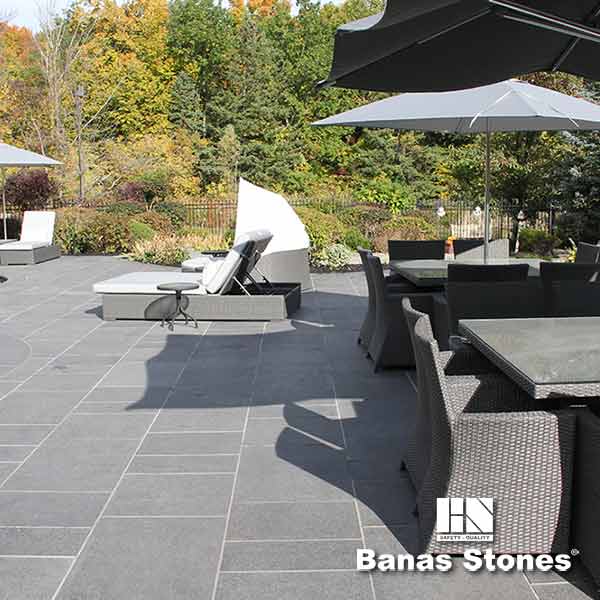

Innovative Uses of Natural Stone in Commercial Projects

Choosing the Right Sandstone for Your Home: A Comprehensive Buyer’s Guide

Enhance Your Outdoor Space with Natural Stone

Designing Your Dream Patio: How to Incorporate Natural Stone for a Stunning Outdoor Space

About Us

Banas Stones® is a major natural stone supplier and exporter throughout North America with a primary focus on establishing our own infrastructure and quarries ensuring excellent quality products.

All natural stone is quarried ethically with the highest safety and ethical standards.

Learn More

Top Quality Hand Selected Stone

Our Promise

Life Time Warranty

We confidently offer our customers the highest quality, ethically produced and environmentally sustainable natural stone products that are quarried with pride. Banas Stones has been offering premium quality stone products and excellent customer service for the last 25 years. Banas Stones offers our customers the highest quality of ethically produced and environmentally sustainable natural stone products that are quarried with pride.

Banas Stones Limited Lifetime Warranty guarantees that from the date of purchase our products including but not limited to all sandstone, limestone and granite pavers, coping/treads, steps/risers, pier caps and jumbo slabs are free from processing defects. Banas Stones guarantees the structural integrity of all landscaping products for a lifetime of 50 years.

Experience & Expertise

Family Owned

Banas Stones is a family owned and operated company under the Banas Group umbrella which has been offering premium quality stone products and excellent service for over 30 years. With 20 operating quarries we are recognized as a major natural stone provider globally and have a portfolio of some of the most magnificent projects on the planet.

Service Excellence

Banas stones has always put quality first while ensuring timely delivery and competitive pricing simultaneously since our beginnings. Our success is directly linked with the service we deliver. We are dedicated to roll up our sleeves and help. To meet the unique and growing demands of the North American natural stone market and to promote its full range of products, Banas Stones has a distribution centre in Toronto, ON, Canada. The large inventory of premium sandstone, limestone and granite products allows us to provide prompt delivery and excellent service.

Family Owned

Banas Stones is a family owned and operated company under the Banas Group umbrella which has been offering premium quality stone products and excellent service for over 30 years. With 20 operating quarries we are recognized as a major natural stone provider globally and have a portfolio of some of the most magnificent projects on the planet.

Hear It From Them

Discover the reasons why BANAS is the preferred supplier for everyday luxury natural stone products.

Unlock a world of timeless elegance and inspiration!

Subscribe to our newsletter and become apart of Banas Stones Premier circle!

What Awaits You?

- Premier Blogs

- First Glimpse

- Design Inspiration